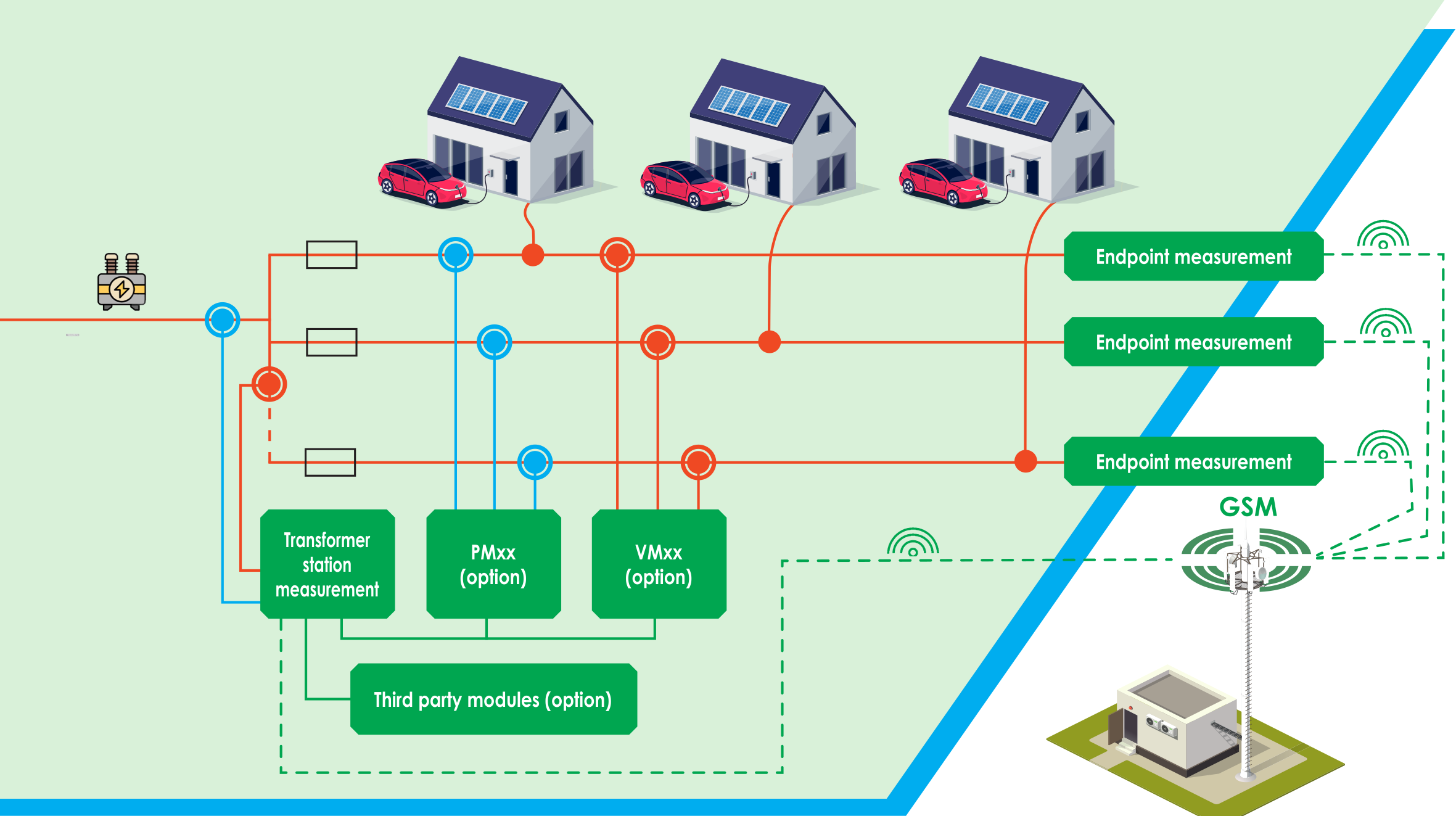

LV Node

TRANSFORMER STATION MEASUREMENTS

The LV-PA34 device performs supply-point measurements on the secondary side of the MV/LV transformer and transmits the data via a communications modem to the data center. Supply-point measurement involves measuring three voltages and three (or optionally four) currents. In addition to generating its own measurement data, the LV-PA34 can communicate with further proprietary or third-party devices and transmit their data as well.

TRANSFORMER STATION BRANCHING MEASUREMENTS

The LV-NODE product family's supply-point central unit, the LV-PA34, can be expanded with additional Prolan-manufactured plug & play expansion modules. This solution makes it possible to monitor multiple branches originating from a single transformer without installing multiple modem-equipped units. The LV-PMxx devices measure branches current and power, while the LV-VMxx devices check for voltage presence.

END-POINT MEASUREMENTS

Within the LV-NODE product family, the LV-VA3 device is the modem-equipped option for voltage measurement at line endpoints. Its feature set is similar to the LV-VA34, but given its intended installation environment, it cannot be expanded with additional modules and does not measure current. As a result, it has a much simpler, more efficient design and installation process.

MAIN FEATURES

- Power quality measurements according to EN 50160, EN 61000-4-30, and EN 61000-4-15

- Voltage measurement accuracy of 0.5%, current measurement accuracy as low as below 1%

- Three-phase voltage measurement with an internal fuse

- Three-phase (optionally four-wire) current measurement using a Rogowski sensor

- Changeable current sensors with IP65 connectors

- LTE 4G communication with either an integrated or external antenna, depending on the model

- Optional GPS location and time synchronization

- Support for multiple IoT protocols (e.g. MQTT, Microsoft Azure)

- Remote configuration and firmware updates

- Up to five minutes continuous measurement and communication in case of power failure

- Operation from a single active phase if needed

- LED status indicators on the device front panel

- UV-resistant, IP65-rated enclosure

- Installation without opening the device enclosure

- Live installation possible (no power shutdown required)

MEASUREMENTS

Periodically Generated Data (Statistics):

- Average, minimum, and maximum for each measured quantity

- Configurable cycle time in minute resolution

- Voltage and current RMS

- Active, reactive, and apparent power

- Power factor

- Voltage and current THD

- Individual voltage and current harmonics

- Voltage and current asymmetry

- Mains frequency

Events, Alarms:

- Voltage dip

- Voltage swells

- Rapid voltage changes

- Overcurrent

- Voltage interruptions

- Medium-voltage line break

- Door opening

Other Data:

- Flicker Pst1 and Pst10

| Operating voltage range | 100…280 VAC |

| Power consumption | 3 W (average), max. 5 W |

| Operating temperature | -20…70 °C |

| Voltage measurement | 3-phase |

| Voltage measurement accuracy | ≤0.5% |

| Voltage measurement range | 0…280 VAC |

| Voltage measurement overload capability | 440 VAC (1 minute) |

| Internal fuse | 6.3 × 32 mm, 2A, 500V, I1 ≥ 20 kA |

| Current measurement | Rogowski sensor |

| Current measurement accuracy | ≤1% |

| Current measurement range | 30…3000 A |

| Trip threshold for current measurement | max. 2 A |

| Current measurement overload capability | 20 kA |

| Impulse withstand voltage | 6 kV |

| Insulation strength | 2.5 kVeff |

| Power supply holdup time | 5 minutes |

| Module power supply | From network through voltage measurement |

| Sampling frequency | 32 kHz |

| Internal clock accuracy | <1 s/day |

| Remote communication | LTE 4G, GPRS |

| Communication protocols | MQTT, MS Azure IoT Hub, Mender.io, NTP |

| Local communication | 2 × RS485 |

| IP protection | IP65 |

| Mounting | With screws or band clamp (max. 18 mm width) |

-(3)-thumb.jpg)

-(2)-thumb.jpg)

-(1)-thumb.jpg)